%20Small.jpg)

Home Brew Audio Switch

%20Small.jpg)

|

I completed this project in Nov 2015. My original

inspiration for this project was to have a central audio switching unit I could

select audio from various radios in my collection and apply the audio to a

master central speaker. It was a simple concept that grew to way overkill but

also way cool.

It would have 10 selectable inputs. This was based on the rotary switch

I had available in the parts bin. I chose to use a line input impedance of

500/600 ohms at a reference level of 0dbm. This was chosen as many radios have a

500/600 ohm line output. I incorporated provision for radio’s that only had an 8

or 4 ohm output. I accomplished this by using 4 line transformers that would

transform the 8/4 ohm inputs to 500 ohms which could then be wired into one of

the available ten 500/600 ohm inputs. One of those line transformers was also

setup to select between 8, 4, and 16 ohms to account for at least one input that

may be 16 ohms.

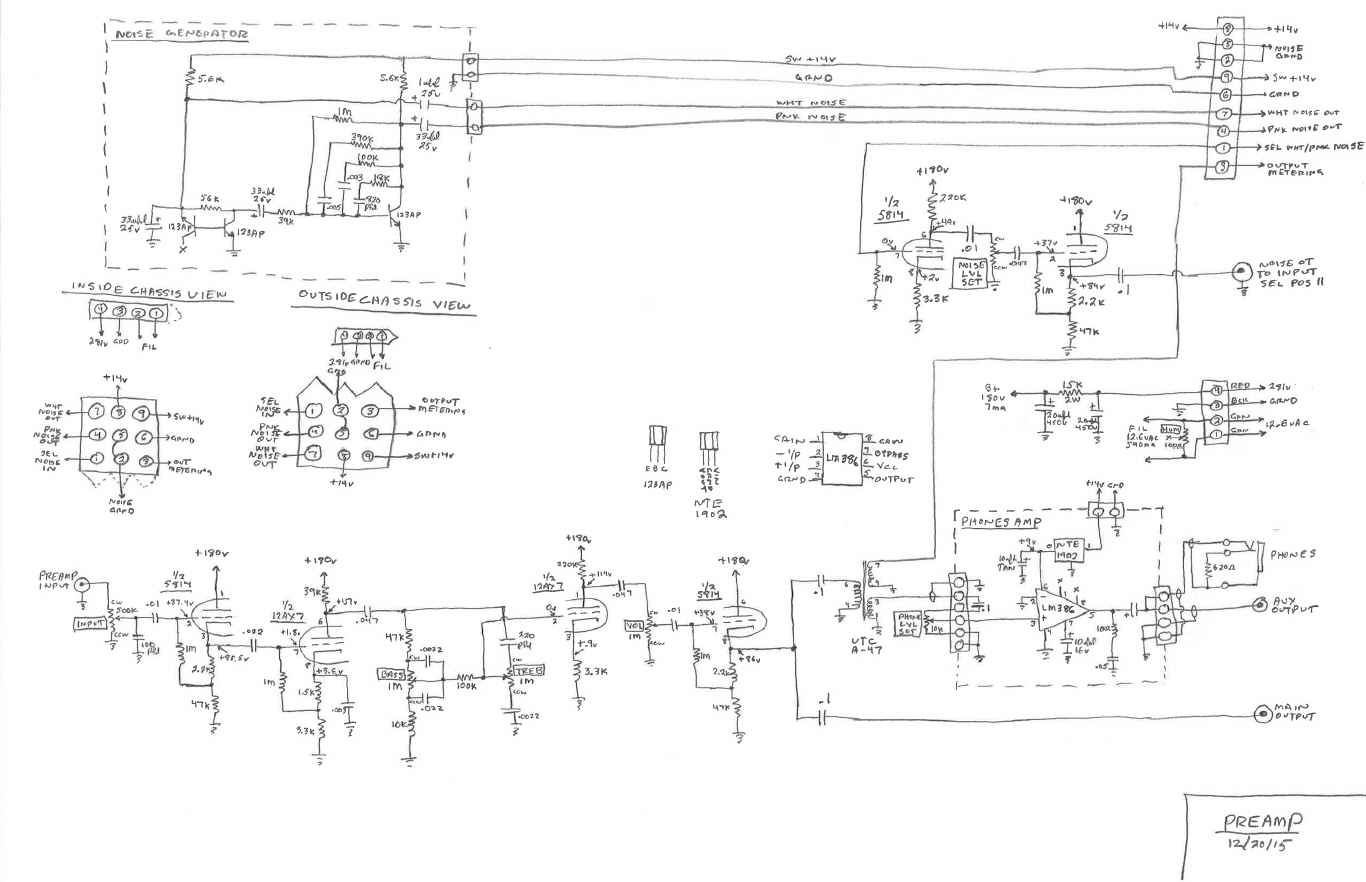

I had a couple audio devices that I decided to incorporate into the

project that included a Yamaha GQ1031Graphic Equalizer and a Heathkit HD-1418A

Active Audio Filter. Both of these devices are switchable as either in-line or

bypassed in the audio path. I have a Heathkit W5M PA used externally as the

final audio PA feeding an external Jensen speaker. I needed some type of pre-amp

to drive the W5M so I borrowed the Heathkit WAP2 pre-amp circuitry and built a

pre-amp into the Audio Switch.

For metering I wanted to be able to monitor the input, output at the

equalizer, output at the Active Audio Filter and output from the pre-amp which

is also the output of the Audio Switch. I made provision for both internally

monitoring and external monitoring if it was desired to connect an external AC

Voltmeter for more accurate audio monitoring and signal measurement. |

Build Out

| Pre Amplifier | ||

|

%20Small.jpg) |

%20Small.jpg) |